The Engine Behind DW1: Richard Gravely Named CEO of DW1

At DW1, leadership has always meant more than titles. It is about service, resilience, critical thinking, and the ability to turn challenges into opportunities. Today, we are proud to announce a major milestone in our company’s story.

Richard Gravely, our longtime President and first employee, has officially transitioned into the role of Chief Executive Officer after nearly 25 years of dedicated service.

This is more than a well-earned promotion. It reflects the natural evolution of a leadership journey built on operational excellence, disciplined decision-making, and an unwavering commitment to the people who make DW1 what it is today.

An Engineer’s Mind, A Servant’s Heart

Before joining DW1, Richard spent over a decade in the fiber optics industry as a Product Manager, honing his expertise in technical operations, systems thinking, and customer-centered solutions. His engineering background remains a cornerstone of his leadership style.

Richard approaches every challenge with a methodical, analytical mindset, carefully balancing innovation with operational discipline. His ability to assess complex situations, anticipate obstacles, and implement decisive solutions has kept DW1 on a consistent growth trajectory year after year.

A Pillar of DW1 from the Start

When DW1 was founded, Richard Gravely was there from day one — wearing every hat, facing every obstacle, and building the operational foundation that would set the company apart. From managing accounts and leading sales efforts to overseeing financial operations and developing internal teams, Richard has been the steady force driving DW1’s success.

While our Founder, Ed Foye, cast the visionary roadmap, Richard turned that vision into reality. He handled the daily fires, made critical decisions, and served as the grounding influence that kept DW1 focused, stable, and moving forward.

One of Richard’s greatest strengths is his ability to listen deeply to his team. His genuine care shines through in every conversation. He values diverse perspectives and actively encourages input from every level of the organization. Even when long-standing habits create resistance, Richard challenges individuals to evolve, adapt, and embrace new approaches. His leadership has kept DW1 agile, competitive, and positioned for future success.

His servant leadership style fosters resilience, inspires personal growth, and empowers people to lead with purpose.

A Legacy of Growth and Stewardship

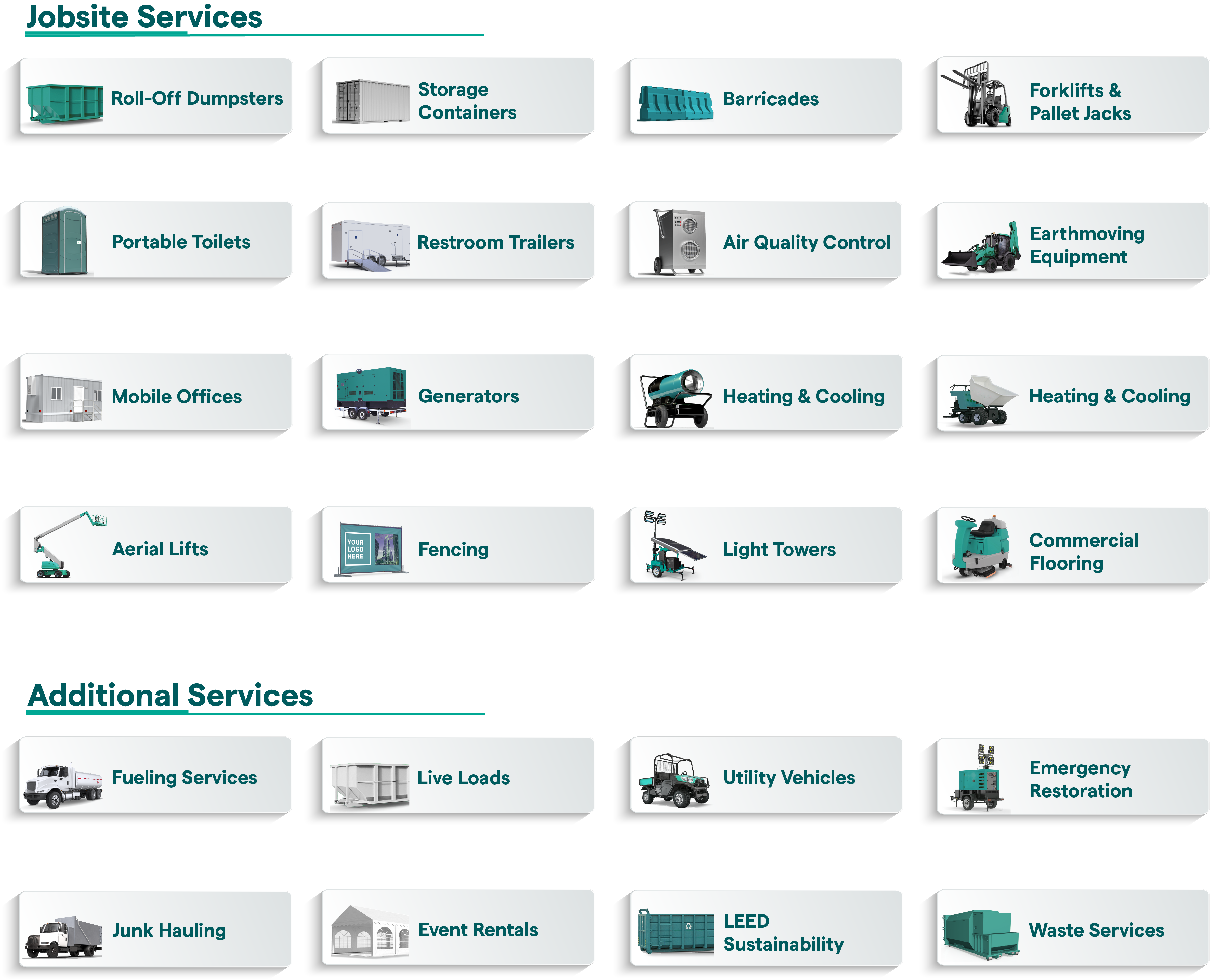

As President, Richard helped drive DW1’s remarkable expansion across equipment rental, waste management, and emergency restoration services. We have built trusted partnerships with contractors, retailers, and restoration professionals across the country.

Richard’s leadership also helped spearhead DW1’s evolution into a technology-enabled organization. By building an in-house enterprise software platform based on his proven business processes and operational procedures, he positioned DW1 to scale efficiently and innovate from within.

Even as DW1 expanded nationally, Richard ensured that our core values remained at the heart of everything we do. His focus on people-first leadership has built a culture rooted in loyalty, camaraderie, and continuous improvement.

From his earliest days managing client relationships directly, Richard defined the standard of customer service excellence that DW1 is known for today. He has always prioritized making the customer experience seamless, responsive, and exceptional.

Looking Ahead with Confidence

As Richard steps into the role of CEO, DW1 is ready to enter its next era of innovation, service, and growth. His operational expertise, commitment to servant leadership, and dedication to empowering our people will guide us forward as we continue to lead, evolve, and serve.

Richard embodies the spirit of DW1: resilient, disciplined, humble, and relentlessly focused on excellence. Under his leadership, we are not simply preserving success; we are building a future filled with new opportunities, deeper partnerships, and a renewed commitment to the mission that has defined us from the start.

The future is not just bright. It is limitless — fueled by the foundation Richard helped build and the possibilities he will help us unlock.

Our entire DW1 family is deeply grateful to have been led by Richard for so many years. We cannot fully express how much his personal care, not only for our business development but also for our personal lives, has meant to every one of us. His investment in people goes far beyond professional growth, creating a culture of trust, loyalty, and genuine support that will continue to shape DW1 for generations to come.

Please join us in congratulating Richard Gravely on his new role as CEO. The best chapters of DW1’s story are still ahead, and we are proud to have Richard leading the way.

Learn more about DW1 and our mission at www.dw1.com

Proactive Planning: The Key to Efficient Equipment Use

Proactive Planning: The Key to Efficient Equipment Use